In the United States, manufacturing contributes $2.65 trillion to the economy and employs almost 13 million workers. People who want to drive innovation and create solutions to the world’s biggest challenges often turn to this industry to help build a thriving future for humanity. Whether in biotechnology or industrial settings, manufacturing technician jobs allow people to innovate every day.

As technology continues to reshape the manufacturing landscape, now is an exciting time to become a manufacturing technician. The first step for detail-oriented, technical individuals who want to pursue this career is understanding what a manufacturing technician does and how to begin their journey.

Table of Contents

- 1. What Is a Manufacturing Technician?

- 2. What Does a Manufacturing Technician Do?

- 3. Manufacturing Technician Salary and Job Outlook

- 4. Manufacturing at Danaher

- 5. How to Become a Manufacturing Technician

- Identify Career Goals

- Complete Your Education

- Gain Hands-On Experience

- Become Certified

- Explore Professional Development Opportunities

- Master Soft Skills

- Elevate Technical Skills

- Build a Professional Network

- Create a Manufacturing Technician Resume

- Include a Cover Letter

- Apply for Manufacturing Technician Jobs

- Focus on Effective Interviews

- 6. Join a Team of Manufacturing Engineers That Transform Human Health at Danaher

- 7. Build the Future of Health With Manufacturing Technician Jobs at Danaher

What Is a Manufacturing Technician?

A manufacturing technician works hands-on in manufacturing, overseeing processes, improving products and conducting quality assurance assessments. This detailed work includes setting up, running and monitoring manufacturing processes. Professionals use technical and mechanical skills in biotechnology, machine tool manufacturing and aerospace.

In addition to quality assurance, manufacturing technicians provide technical support for manufacturing operations. They troubleshoot equipment and process issues to ensure smooth operations in a manufacturing environment. They work autonomously and collaborate with production, operations, safety and other departments to ensure projects get completed on schedule.

What Does a Manufacturing Technician Do?

[Manufacturing technicians play a pivotal role in innovation, quality assurance and optimizing business processes.]

While manufacturing technicians create products, their roles and responsibilities vary by employer and industry. A typical manufacturing technician job description involves:

- Engaging in cross-departmental collaboration: Technicians work closely with other employees and departments in manufacturing processes.

- Ensuring effective manufacturing processes: A manufacturing technician’s primary responsibility involves ensuring parts meet quality expectations. They set up machinery, enter specifications into computers and monitor the stages of manufacturing processes.

- Assessing product quality: A manufacturing technician will inspect completed products and parts for flaws. They can then inform future processes to prevent wastage and improve product quality.

- Troubleshooting and maintenance: Manufacturing technicians troubleshoot machinery issues and perform basic repairs. They oversee the inspection, cleaning and maintenance of machines.

- Reducing waste and maintaining profitability: Manufacturing technicians apply manufacturing principles and create procedures to reduce output variation.

In addition to these primary tasks, manufacturing technicians will also cover the following responsibilities:

- Improve safety and productivity.

- Create workplace layouts to boost efficiency.

- Work with new hires to inform them of best practices and safety requirements.

- Create maintenance logs and progress reports.

- Interpret schematic diagrams and formulas.

- Collect data to assist in process improvement.

What Manufacturing Technicians Do at Danaher

In the Danaher Business System (DBS), manufacturing technicians contribute to the development of high-quality, life-changing products across scientific and technological fields. Our manufacturing technicians are instrumental in:

- Operating and monitoring equipment: From semi-automated machinery in medical device manufacturing to batch processing in chemical production, technicians manage the tools that bring our innovations to life.

- Ensuring quality and compliance: Manufacturing technicians implement standard operating procedures, work specifications and regulatory requirements to ensure every product excels at its purpose.

- Improving processes: These technicians use DBS tools and Lean techniques to optimize efficiency, reduce waste and enhance productivity.

- Maintaining documentation: Our manufacturing technicians record production data, log maintenance activities and keep all records precise and complete.

- Troubleshooting and maintaining equipment: We rely on manufacturing technicians to proactively address machinery issues and perform maintenance tasks, maximizing uptime and ensuring smooth operations.

Across our businesses in life sciences, diagnostics and biotechnology, manufacturing professionals perform challenging, hands-on work that involves assembling innovative medical and research devices, including handling fragile components. For example, manufacturing technicians at Radiometer–a Danaher diagnostics business that specializes in blood gas analysis, transcutaneous monitoring, and immunoassay testing–sand and clean delicate ceramic substrate boards.

While a postsecondary degree can be a competitive advantage, strong candidates for these positions may have a high school diploma or equivalent with relevant work experience. Experience in regulated environments, such as medical device or chemical manufacturing, is especially valuable. Attention to detail when following instructions and a commitment to safety are essential for technicians in manufacturing teams across all of our businesses.

Types of Manufacturing Technician Roles

One of the best things about choosing a manufacturing technician career is the volume of roles candidates can pursue. Candidates can solve problems and push the boundaries of possibility while following their passions. Some of the many manufacturing technician roles include:

- Certified production technician (CPT): An accredited production technician ensures regulatory compliance and meets production goals. They work in manufacturing and industrial settings, and many specialize in maintenance awareness and safety protocols.

- Mechatronics technician: These professionals operate, test and maintain computer systems and electromechanical equipment. They also design and implement solutions that streamline processes for repetitive or time-consuming tasks.

- Biotechnology manufacturing technician: Biotechnology manufacturing technicians have specialized skills and carefully control the environment where biological processes happen. They carry out complex processes, monitor equipment and collaborate with other departments to define, design and execute critical biomanufacturing processes.

- Quality assurance technician: Quality assurance technicians, or quality control analysts, specialize in testing. They evaluate raw materials, products in the manufacturing process, and completed items for flaws and deviations from specifications.

- Industrial maintenance technician: This role involves installing and maintaining complex mechanical and industrial equipment.

- Robotics technician: A robotics technician configures, tests, maintains and operates robotic equipment. They work with robotics engineers to test new designs and improve production processes.

Manufacturing Technician Salary and Job Outlook

[Professionals in manufacturing enjoy meaningful careers that impact something bigger than themselves.]

The U.S. manufacturing industry could require around 3.8 million jobs to be filled by 2033. Those entering this innovative industry can fill the skills gap and participate in projects that change lives. As of 2024, professionals earn an average of about $52,000 per year. Manufacturing technicians with additional skills or experience can earn up to $73,000 a year, and those seeking entry-level jobs can expect to earn around $37,000 annually.

As innovative technology drives the need for adaptability, the manufacturing industry enters a new era. People joining the industry will be at the forefront of innovation, driving green software and leveraging artificial intelligence (AI) to streamline processes. Regardless of their chosen specialization, future manufacturing technicians will combine technology with their ingenuity to discover new solutions to some of the world’s greatest challenges.

Manufacturing at Danaher

Across our diverse portfolio of operating companies, Danaher is at the forefront of manufacturing that powers breakthroughs in biotechnology, diagnostics and life sciences:

- Aldevron specializes in producing nucleic acids and proteins, including plasmid DNA, RNA and gene editing enzymes. These components are vital building blocks for advanced gene and cell therapies. Aldevron has a growing campus in Fargo, North Dakota.

- Cepheid produces accurate, user-friendly molecular systems and tests, including the GeneXpert® Xpress System. Their manufactured solutions provide rapid diagnostic capabilities to combat infectious diseases like tuberculosis. The Cepheid facility in Bangalore, India, is a key outpost in Danaher’s global mission to advance human flourishing.

- Cytiva provides essential bioprocessing technologies like chromatography resins, filtration systems, single-use bags and cell culture media. Their manufacturing supports the large-scale production of biologics and cutting-edge therapeutics, ensuring a robust biopharmaceutical supply chain. Cytiva’s expansive bioprocessing supply manufacturing network includes Europe, Asia-Pacific and North America.

- Integrated DNA Technologies (IDT) manufactures specialized cGMP cell and gene therapy reagents, including single guide RNAs and donor oligos. Their precision manufacturing supports the development of advanced diagnostics and empowers scientists to accelerate genomic research, guiding breakthroughs from vaccine development to disease diagnosis. IDT has a cutting-edge cGMP therapeutic oligonucleotide manufacturing facility in Coralville, Iowa.

- Pall Corporation is a global leader in high-tech filtration, separation and purification solutions. They manufacture critical equipment and consumables to help produce biological therapeutics, including vaccines. Pall Corporation manufacturing hubs include Bad Kreuznach, Germany, Newquay, UK and Singapore.

- Radiometer manufactures acute care diagnostics equipment, including blood gas analyzers. These precision instruments enable rapid and reliable patient diagnoses, empowering medical professionals to make informed decisions that save lives. Key Radiometer manufacturing sites are located in Carlsbad, California, and New Brighton, Minnesota.

Why Danaher Is a Manufacturing Leader

Manufacturing technicians seeking to join industry-leading teams will find several key differentiators at Danaher companies:

- The Danaher Business System (DBS): DBS embeds a culture of continuous improvement that drives ecosystem-wide excellence across our manufacturing sites.

- Global scale: Danaher invests in expanding manufacturing capacity and capabilities across continents, ensuring resilience, speed and the ability to meet growing global demand for advanced scientific products.

- Innovation at speed: Our manufacturing teams are adept at scaling production for novel technologies, rapidly transitioning from research-use-only products to cGMP-grade materials to propel therapies from lab to clinic.

How to Become a Manufacturing Technician

Becoming a manufacturing technician involves following several steps.

Identify Career Goals

[Candidates should choose careers that align with their passions, which leads to greater fulfillment.]

Before embarking on a career path, professionals should identify their goals and passions. People who pursue careers they care about enjoy increased motivation, make fewer mistakes, learn quickly and make better business decisions. With solid career goals, they can drive innovation and make a meaningful difference in many lives. Some tips and tricks for professional goal-setting include:

- Pinpointing an overarching career goal: Each professional should identify their goal, such as improving lives or advancing their careers. From there, candidates can narrow down short-term goals that propel them toward their long-term goals.

- Learning new technologies: Adopting new technologies drives manufacturing innovation. Manufacturing professionals can set goals to learn more about these technologies and aim to integrate these tools and systems into their processes.

- Improving productivity and efficiency: Professionals can analyze their performance, including the quality of their work, to track progress toward their goals and steadily improve performance.

- Landing an internship at a high-value organization: Candidates can set goals to intern at a company that drives innovation and fosters a supportive culture. They should thoroughly research the company and determine the skills and experience required for a successful internship.

Complete Your Education

Candidates seeking a career as manufacturing technicians typically need a high school diploma or equivalent plus relevant experience. An associate or bachelor’s degree in manufacturing technology, industrial engineering or a related field can be an advantage, depending on the role and company. These programs provide a foundational understanding of manufacturing, machinery and quality control processes.

The term “manufacturing technician” encompasses a broad range of roles. Education and training requirements vary significantly depending on the complexity of the candidate’s desired job. For example, a biotechnology manufacturing technician could obtain a degree in biotechnology, biomanufacturing or industrial pharmaceutical technology.

Some organizations require additional technical education or specialized vocational training, especially in high-tech manufacturing, biotech and medical device manufacturing. Students can expect to study computer-aided design (CAD), lean manufacturing, automation, robotics and project management.

Gain Hands-On Experience

[Hands-on experience allows professionals to get the technical expertise they need to enter the job market and make an impact.]

Much of a manufacturing technician’s job requires hands-on technical skills that candidates may not find in the classroom. In addition to sharpening these technical skills, hands-on experience demonstrates a professional’s readiness. Candidates can look for the following hands-on learning opportunities:

- Apprenticeships: An apprenticeship allows candidates to gain manufacturing work experience while earning a salary. Most manufacturing apprentices earn an hourly wage, making it easier for candidates to enhance their skills.

- Internships: Job seekers can acquire the relevant skills and potentially work toward full-time employment with companies that offer internships. Depending on the organization, these internships may be available to people entering the workforce or changing jobs.

- Volunteer work: Individuals can focus on nonprofits that manufacture items to gain some skills while giving back to their communities.

- Temporary positions: Temporary jobs offer excellent opportunities for work experience. They allow candidates to explore the workplace, understand company culture and build relationships without a full-time commitment. Candidates who make an impact may be considered for full-time employment.

Become Certified

Job seekers looking to expand their careers or stand out in a pool of applicants benefit from additional certifications, which help them grow and showcase their unique skills. Completing one or more professional certifications enables candidates to maintain consistent manufacturing quality and enhance their professional credibility.

Depending on their chosen roles, candidates can choose from the following manufacturing certifications:

- Manufacturing technician level 1 (MT1): This certification, offered by the Manufacturing Skills Institute, addresses core skills required for manufacturing occupations in all sectors. It allows candidates to master the critical competencies necessary for successful careers.

- Certified automation professional (CAP): Candidates who complete this International Society of Automation certification will learn more about automated processes, system designs and deployment.

- Certified production technician (CPT): The Manufacturing Skill Standards Council offers this program, which provides professionals with valuable knowledge of production processes and covers topics such as safety, maintenance awareness and quality measurement.

- Certified quality engineer (CQE): This American Society for Quality program helps professionals understand the processes of evaluating production services and products. It focuses on the detailed principles and practices of quality engineering.

Explore Professional Development Opportunities

[Job seekers must take advantage of professional development opportunities to stay agile in a changing space.]

Manufacturing is a rapidly changing sector, and candidates benefit from a comprehensive understanding of the industry. They should stay current on the problems, innovations and industry trends relevant to their careers. Individuals have access to many professional development opportunities throughout their careers, including:

- Online courses: Online programs provide professionals with convenience and accessibility for learning new concepts, tools and techniques in manufacturing operations. Job seekers can complete short-term certificates and online degrees in various topics, including lean manufacturing, quality management and many others.

- Industry associations: Joining industry associations provides professionals with valuable resources, including newsletters, standards, publications and webinars. They help professionals stay informed of the latest trends and best practices in manufacturing.

- Mentors: Candidates can also seek guidance and feedback from innovators in their field. These mentors and coaches can help them navigate their careers and overcome challenges. New technicians can also benefit from coaches — trained and certified professionals who help them improve their skills.

- Forums and online communities: These platforms allow professionals to interact with peers, ask questions and share experiences. Candidates can find them on social media and apps dedicated to manufacturing operations.

Master Soft Skills

[Candidates who master soft skills have a competitive edge with employers.]

One of the most prominent trends in the job market involves the greater emphasis on soft skills. As technology continues to take over repetitive, time-consuming tasks, employers become more interested in these skills because they remain relevant regardless of technological advancements. Candidates looking for a competitive edge should learn the following in-demand skills:

- Communication and collaboration: Manufacturing technicians must work with other employees and departments to maintain the highest levels of quality and compliance. Their ability to collaborate can drive results; one report shows that employees who collaborate are 60% more innovative.

- Strategic thinking: Manufacturing technicians must display strong strategic thinking and problem-solving skills to ensure the productive use of resources. They must spot inconsistencies quickly, create cohesive plans and devise creative solutions.

- Attention to detail: Manufacturing involves many specific steps, and errors in one can impact the entire result. Manufacturing technicians must observe these steps and identify discrepancies early.

Elevate Technical Skills

In today’s technological world, digital literacy, data analysis and other technical skills provide the foundation for many careers. Aspiring manufacturing technicians must have proficiency in various software tools, digital platforms and other technologies to perform their tasks effectively. Many of these skills depend on their chosen specialization, but some general technical skills include:

- AI learning: Today’s manufacturing technicians will work with AI in some capacity. They should have a basic understanding of AI tools that help organizations streamline processes and focus on innovation.

- Data analysis: Data drives unique innovation and discovery in manufacturing. Aspiring manufacturing professionals benefit from the ability to interpret data and uncover beneficial insights.

- Technical writing: Manufacturing technicians must fill out maintenance forms, draft compliance documents and simplify complex concepts, which becomes easier with technical writing skills.

- Numerical understanding: Manufacturing technicians’ daily work requires strong mathematical and measurement skills. They must be able to follow formulas and numerical factors to execute procedures correctly.

Build a Professional Network

[Candidates with a robust professional network may have access to opportunities and work experiences that advance their careers.]

A robust professional network benefits candidates in all fields. Nurturing connections with professionals in their field can spark new opportunities for candidates. Networking involves building relationships that create mutual value, meaning candidates must prepare to bring value to their connections, too. Professionals aspiring to careers as manufacturing technicians will benefit from the following networking tips:

- Stay in contact with former co-workers and classmates: Candidates can periodically check in with past connections. It might spark conversations that lead to new opportunities.

- Attend networking events: Industry-specific and general business events allow candidates to expand their professional networks. Candidates can also attend conferences, which provide networking and ongoing learning opportunities.

- Use social media: Professional networking sites like LinkedIn can help candidates build their reputations and networks. They should post, comment, and share industry-specific information while maintaining genuine communication. Over time, they will attract like-minded people and build an engaged online network.

- Connect people: Candidates can also introduce others who would benefit from each other, amplifying the value they bring to their networks.

- Request mentorships: Requesting mentorship from industry leaders helps professionals advance their careers and make lasting professional connections.

- Maintain meaningful connections: A professional network takes time to build. When a candidate establishes a strong relationship, they must try to preserve it by making periodic contact and adding value.

Create a Manufacturing Technician Resume

As the demand for skilled manufacturing professionals rises, so does the competition for those positions. Candidates must craft a resume that stands out. Professionals can explore these tips and tricks for creating an attention-grabbing resume:

- Include contact information: Candidates should include their full name, state of residence, contact number and email address. They should make it easy for employers to find and contact them for an interview.

- Write a professional summary or objective statement: Candidates should introduce their resume with a few sentences that describe their manufacturing technician skills and experiences. Experienced applicants can opt for a professional summary describing their experience and the value they brought to past employers.

- Use the job description: Candidates can tailor their resumes to reflect the language used in the job posting. They should use the phrases and words the potential employer has used to describe the necessary experience and skills. Candidates new to the job should write an objective statement describing who they are, why they want the job and their career objectives.

- Pay attention to the details: Most employers look for keen attention to detail in manufacturing technicians. Candidates can demonstrate this with a grammatically correct resume.

- Highlight relevant experience: Any candidate benefits from highlighting their expertise. Even new candidates can showcase volunteer work, internships and clubs.

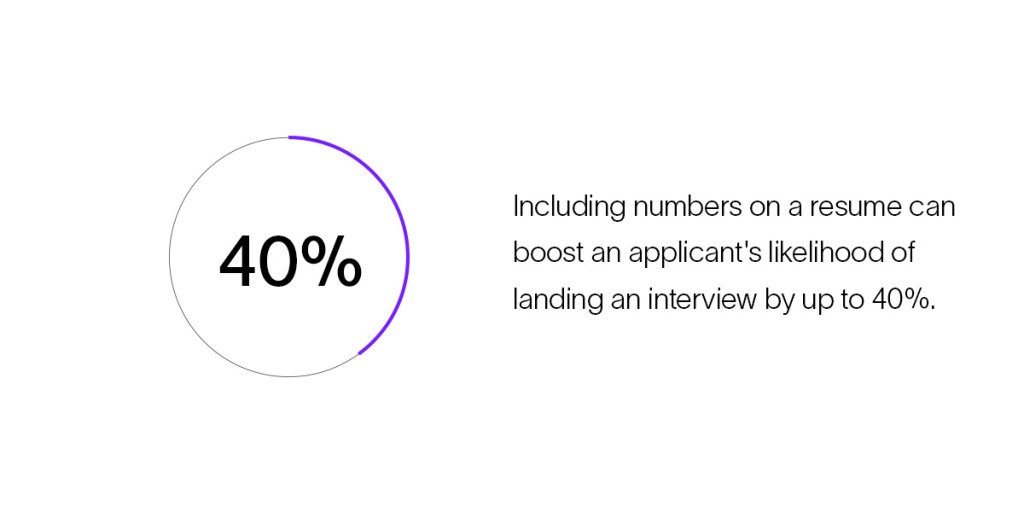

- Quantify impact: Candidates should use metrics to illustrate their value wherever possible. Numbers provide evidence of a candidate’s positive impact. When included on a resume, they increase an applicant’s likelihood of landing an interview by up to 40%.

Include a Cover Letter

A cover letter for manufacturing technicians is more than a repeat of their resumes. It offers applicants the chance to personalize their interactions with recruiters and stand out from other candidates. Applicants can take the following steps to craft a professional cover letter:

- Focus on formatting: A cover letter should include a header, salutation, introductory paragraph, body paragraph and signature. Applicants should stick to simple fonts and keep their cover letters to less than a page. They should keep the content organized, structured and relevant to their prospective jobs.

- Showcase problem-solving skills: Manufacturing processes often encounter challenges, and recruiters prefer candidates who can provide solutions to these issues.

- Complement the resume: A cover letter should help the employer get to know the applicant better and complement the resume, making it easier for the employer to evaluate the applicant’s suitability for the position.

- Be concise: A cover letter should avoid flowery or unnecessary language. Candidates should keep it between 250 and 400 words to keep readers engaged.

- Tailor the cover letter to the job: Candidates should avoid using generic templates and address the company and role specifically, using the same technique they used for their resumes.

Apply for Manufacturing Technician Jobs

When applying for manufacturing technician jobs, candidates should focus their efforts on organizations that will support them as they advance their careers. Researching each company is one of the most critical steps of the job application process. It shows the company that the applicant took the time to determine whether their career goals align with the company’s mission.

Displaying an authentic interest in the organization also helps applicants relate. Applicants can browse each company’s website to understand its culture, values and mission. They can also contact current employees to learn about daily operations and research competitors to better understand the industry. Once candidates have completed their research, they can adjust their resumes and cover letters to align with the organization’s goals.

Focus on Effective Interviews

Once an organization contacts a candidate for an interview, they can start preparing. Prospective manufacturing technicians can prepare for specific interview questions. They should prepare to discuss the types of machinery they have experience with, their understanding of safety regulations and the steps they can take to troubleshoot issues.

Interviewers want to gauge applicants’ technical competency and familiarity with the relevant equipment. Candidates should prepare to demonstrate their understanding and industry experience. In addition, manufacturing technicians regularly face unique issues that require swift and practical solutions. Employers will likely ask questions about critical thinking and decision-making. Candidates should respond with examples of problems they’ve solved and the impact of their solutions on their organization.

Join a Team of Manufacturing Engineers That Transform Human Health at Danaher

Any candidate ready to grow their career and amplify their impact on the world will achieve their goals at Danaher. As a Danaher manufacturing engineer, candidates can thrive in a culture where each person’s viewpoint matters. Individuals can harness Danaher’s system of continuous improvement to turn their ideas into realities and make meaningful differences that save lives.

Danaher comprises diverse businesses at the forefront of biotechnology, diagnostics and life sciences. Each company in our ecosystem remains dedicated to advancing innovation to make a quantifiable, far-reaching impact. With us, candidates can tackle some of the world’s greatest challenges and leverage DBS to amplify their innovations. As a Danaher manufacturing technician, candidates can expect to perform the following duties:

- Lead small teams.

- Find creative, impactful solutions.

- Focus on efficiencies.

- Support production teams.

- Work cross-functionally.

- Manage projects.

Our unique processes inspire and challenge team members daily. As part of a collaborative team, individuals have access to leaders in the field and work with teams worldwide. Everyone focuses on the same goal — improving lives. We embrace each unique viewpoint and believe it’s the key to making an impact.

Our manufacturing technicians support our teams, helping us streamline performance, reduce waste and accelerate our contributions to society. Ambitious high performers thrive at Danaher, and we love hearing from people who feel passionate about process improvements and refining their technical expertise.

Danaher team members can expect engaging and transparent conversations where they learn more about the unique vision that drives our businesses. We want our team to excel, and we work hard to create a symbiotic experience.

Build the Future of Health With Manufacturing Technician Jobs at Danaher

[Push the boundaries of possibility with manufacturing technician jobs at Danaher today!]

A manufacturing technician job offers an opportunity to make a genuine difference in people’s lives. In biotechnology, you’ll be at the forefront of experiments that save lives. At Danaher, we push the boundaries of what’s possible, allowing you to work alongside industry leaders who care about your success. As a global force in biotechnology, diagnostics and life sciences, we support our team throughout their careers.

With us, you’ll see the impact of your work and collaborate on life-changing products. Bring your passion and dedication to a team that innovates at the speed of life. Browse our job openings, and join our community today!